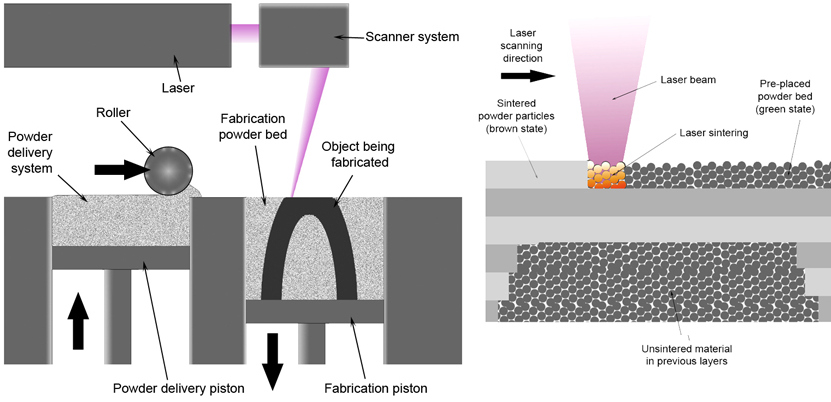

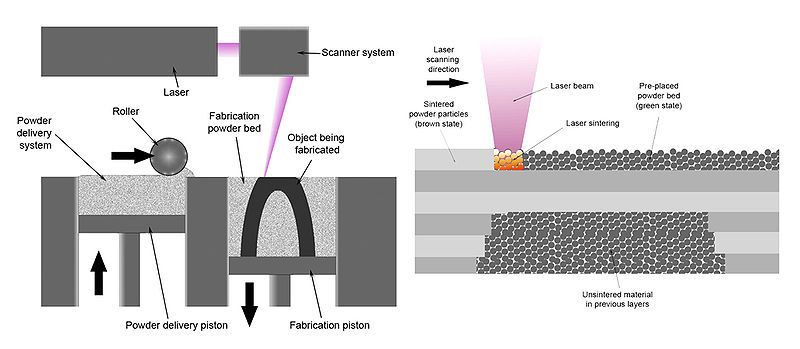

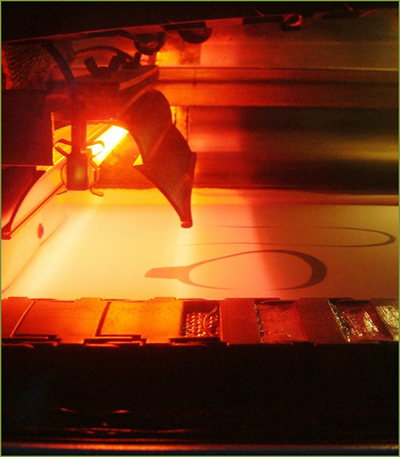

Selective laser sintering sls is an additive manufacturing am technique that uses a laseras the power source to sinterpowdered material typically nylonor polyamide aiming the laser automaticallyat points in space defined by a 3d model binding the material together to create a solid structure.

Laser toner powder manufacturing process.

Scrapinmaniac corner recommended for you.

How a color laser printer works inside an hp 2600 toner cartridge duration.

Toner particles are melted by the heat of the.

Using toner powder with minc machine duration.

The dimensions of the turbine housing are 180 150 mm and build up time is 230 min.

Complex physical events take place during the manufacturing process and.

Like slm sls is another laser based powder bed fusion technique.

It has been developing greatly in the recent decades and being widely used for manufacturing prototyping and repairing.

Heat sensitive plastic powder particles account for the majority about 60 percent of toner powder s composition.

It is 10 times faster than the current powder bed process and machining can be completed without a process chamber works with most materials.

Wax is melted during the printing process to distribute the toner powder on the paper similar to what the plastic does while silica is sometimes added to the toner to stop the powder from clumping up together when it is packed in the toner cartridge.

Toner using plant derived plastic also exists as an alternative to petroleum plastic.

The differences between sls and other powder bed fusion techniques are based on the material options and powder fusing mechanism.

Toner is a powder mixture used in laser printers and photocopiers to form the printed text and images on the paper in general through a toner cartridge.

Selective laser sintering sls was the first process in the powder bed fusion class developed and commercialised.

Groundup sand wax or silica hold the combination of the big three together in the toner.

Like the plastic wax helps to distribute the copier s toner powder across sheets of paper as it melts.

Mostly granulated plastic early mixtures only added carbon powder and iron oxide however mixtures have since been developed containing polypropylene fumed silica and various minerals for triboelectrification.

Silica ground to a fine powdery consistency is sometimes added to prevent the toner solution from clumping.

Small amounts of plastic melt during the laser printing process allowing the toner to adhere to the paper and create an image.

13 2 shows an example of a turbine housing made from stainless steel using the hybrid manufacturing process.

.png)